Login

Contact

Description

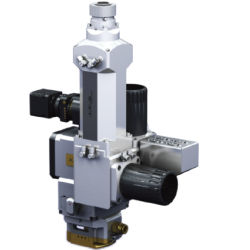

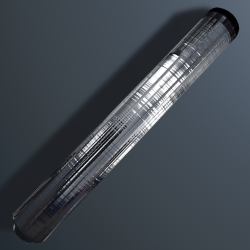

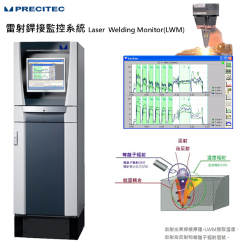

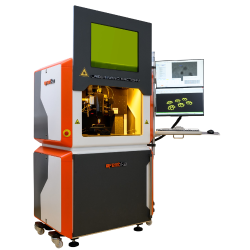

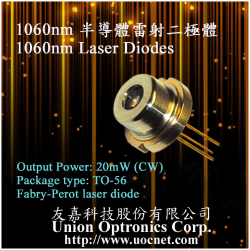

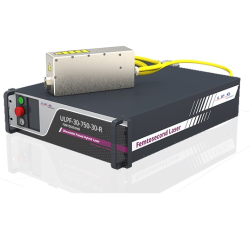

IPG’s new monitoring systems are the next paradigm in industrial weld quality assurance. The LDD-700 weld monitoring system uses Inline Coherent Imaging (ICI) to provide a new level of detail and accuracy for laser weld monitoring. ICI uses a low-power IR laser beam to gauge distances. This measurement beam is fired through the same optics as the welding laser, right to the bottom of the keyhole, and records its depth in real-time. The result is a direct, geometric measurement of weld penetration, acquired in-process. This data is comparable to a cut and etch of the entire length of the weld—for every weld—without destroying the part—and the results are available instantly.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry