Login

Contact

Description

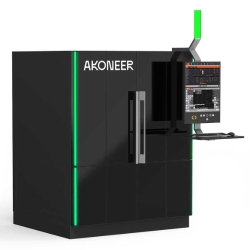

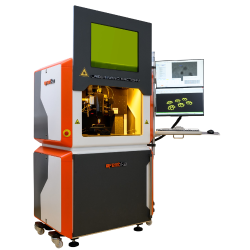

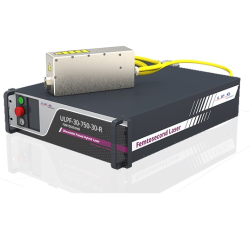

[ Laser Cleaning Machine ]

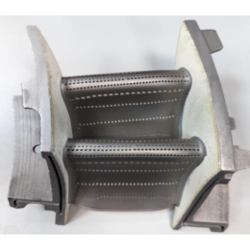

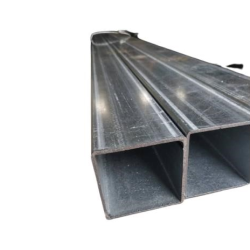

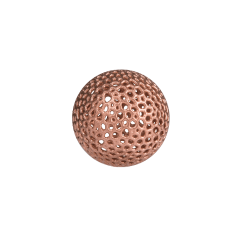

Uses short pulse laser to remove surface oxidized layer, oil, paint or rust instantly, no damage to the substrate, no chemical agent, environmental protection and no pollution.

Suitable for metal repair, mold cleaning, and cultural relics maintenance. Adjustable power and waveform, optimized settings for different materials, a new choice for industrial maintenance and surface treatment.

1.Non-Contact Cleaning

One of the core advantages of the laser cleaner is its non-contact cleaning ability, which does not directly contact the surface of the material during the cleaning process, avoiding mechanical friction or collision, thus reducing the physical damage to the substrate.

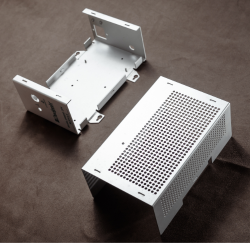

This contactless approach is particularly suitable for materials with complex or fragile surface structures, such as precision electronic components and cultural relics.

Due to the precise adjustment of focus and energy, it is possible to remove only surface contaminants or coatings without damaging the integrity of the substrate.

2. High Efficiency and Energy Saving

Has a very high energy density, can produce a strong thermal effect in a short period of time, so that the pollutants are quickly evaporated or peeled off, and can quickly remove dirt, coatings or oxidized layers on the surface.

Compared with traditional cleaning methods, laser cleaning not only accelerates the cleaning speed, but also saves cleaning time.

Laser cleaning process energy consumption is relatively low, especially in the cleaning process does not require additional chemicals or large amounts of water, which makes the overall operating costs more economical.

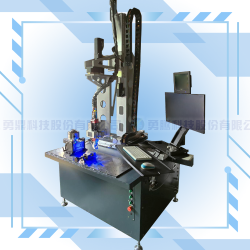

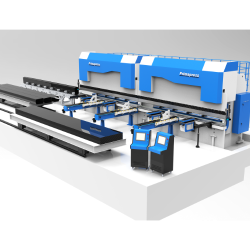

3. Convenient operation and automation

Laser cleaning systems are usually equipped with user-friendly operator interface and intelligent control system, which enables the operator to easily set the cleaning parameters and monitor the process.

Laser cleaning machines can be connected with robot arms or automation devices to realize fully automatic cleaning operations, reducing the reliance on manual operation and improving production efficiency.

This automation feature not only improves work efficiency, but also ensures the consistency and stability of cleaning quality.

4. Environmental protection and safety

As the technology does not use any chemicals or solvents, to avoid the pollution of chemicals on the environment and potential hazards to the health of operators.

Waste generated during the cleaning process is mainly evaporated or peeled pollutants, these wastes are easy to deal with, compared with traditional chemical cleaning methods produced by the waste liquid or harmful gases, laser cleaning is more environmentally friendly.

The working environment is relatively safe and reduces health risks to the operator. It does not produce harmful fumes or gases and does not require high-risk chemical treatment.

Uses short pulse laser to remove surface oxidized layer, oil, paint or rust instantly, no damage to the substrate, no chemical agent, environmental protection and no pollution.

Suitable for metal repair, mold cleaning, and cultural relics maintenance. Adjustable power and waveform, optimized settings for different materials, a new choice for industrial maintenance and surface treatment.

1.Non-Contact Cleaning

One of the core advantages of the laser cleaner is its non-contact cleaning ability, which does not directly contact the surface of the material during the cleaning process, avoiding mechanical friction or collision, thus reducing the physical damage to the substrate.

This contactless approach is particularly suitable for materials with complex or fragile surface structures, such as precision electronic components and cultural relics.

Due to the precise adjustment of focus and energy, it is possible to remove only surface contaminants or coatings without damaging the integrity of the substrate.

2. High Efficiency and Energy Saving

Has a very high energy density, can produce a strong thermal effect in a short period of time, so that the pollutants are quickly evaporated or peeled off, and can quickly remove dirt, coatings or oxidized layers on the surface.

Compared with traditional cleaning methods, laser cleaning not only accelerates the cleaning speed, but also saves cleaning time.

Laser cleaning process energy consumption is relatively low, especially in the cleaning process does not require additional chemicals or large amounts of water, which makes the overall operating costs more economical.

3. Convenient operation and automation

Laser cleaning systems are usually equipped with user-friendly operator interface and intelligent control system, which enables the operator to easily set the cleaning parameters and monitor the process.

Laser cleaning machines can be connected with robot arms or automation devices to realize fully automatic cleaning operations, reducing the reliance on manual operation and improving production efficiency.

This automation feature not only improves work efficiency, but also ensures the consistency and stability of cleaning quality.

4. Environmental protection and safety

As the technology does not use any chemicals or solvents, to avoid the pollution of chemicals on the environment and potential hazards to the health of operators.

Waste generated during the cleaning process is mainly evaporated or peeled pollutants, these wastes are easy to deal with, compared with traditional chemical cleaning methods produced by the waste liquid or harmful gases, laser cleaning is more environmentally friendly.

The working environment is relatively safe and reduces health risks to the operator. It does not produce harmful fumes or gases and does not require high-risk chemical treatment.

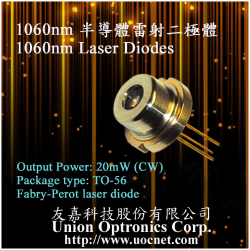

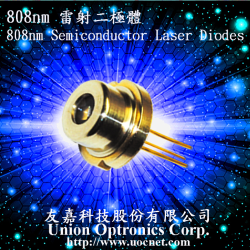

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry