Login

Contact

Description

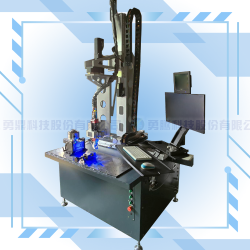

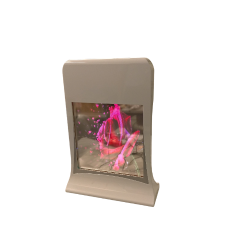

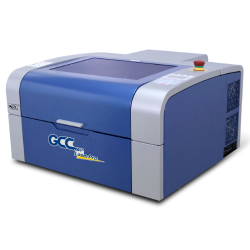

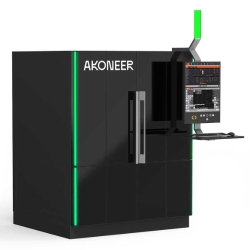

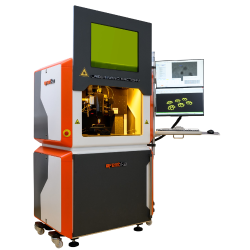

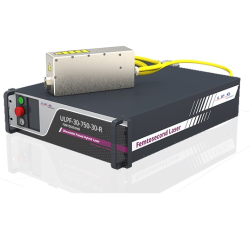

[ Automatic Laser Welding Machine ]

High-energy laser beam for non-contact welding, with low thermal impact, low deformation, and beautiful weld.

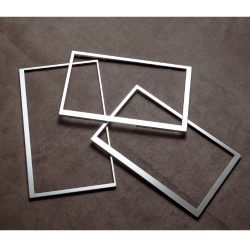

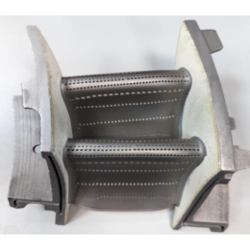

Suitable for high quality welding of precision parts such as battery modules and stainless steel structures.

Supports manual, semi-automatic and fully automatic operation modes, and can be used with robotic arm or visual positioning system for precision processing.

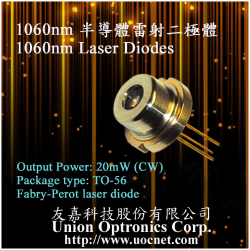

1. High-precision welding

The diameter of the welding point can be as small as millimeters or even microns, which is especially suitable for applications in industrial fields that require a high degree of precision.

For example, in the electronic components, micro-mechanical, medical equipment and other extremely sensitive to small errors in the manufacture of products, laser welding can ensure the accuracy and consistency of the joints.

At the same time, the high precision of welding, but also to avoid excessive consumption of materials, thereby improving product quality and production efficiency.

2. Low thermal impact

Unlike conventional welding techniques, the heat input of laser welding is localized and extremely concentrated.

This means that during the welding process, the surrounding material is only subjected to a very small thermal impact zone, thus avoiding the generation of large-scale thermal deformation or internal stress, and reducing the material cracks or warpage and other problems.

This feature is especially in the welding of thin plates or precision parts to show a clear advantage.

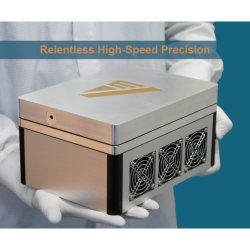

3. High performance and fast processing

laser welding machine has a very high energy density, can complete the welding process in an instant, compared with conventional welding technology has a faster processing speed.

Especially in mass production, can significantly shorten the processing time, improve production efficiency.

Not only that, but also high-speed and stable continuous processing, without frequent machine stops, which is a very advantageous technology choice for such as automotive, aerospace industry and other production areas that require high efficiency and precision.

4. Automation and Intelligence

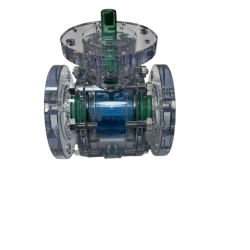

Highly automated welding processes can be realized, whether in simple assembly line production or in conjunction with industrial robots.

Through digital control systems, laser welding can accurately set parameters to ensure stability and consistency from one weld to the next.

Laser welding machines can also be integrated with intelligent monitoring systems for real-time quality inspection and troubleshooting, which not only improves production efficiency, but also reduces downtime and production waste due to improper operation or equipment failure.

High-energy laser beam for non-contact welding, with low thermal impact, low deformation, and beautiful weld.

Suitable for high quality welding of precision parts such as battery modules and stainless steel structures.

Supports manual, semi-automatic and fully automatic operation modes, and can be used with robotic arm or visual positioning system for precision processing.

1. High-precision welding

The diameter of the welding point can be as small as millimeters or even microns, which is especially suitable for applications in industrial fields that require a high degree of precision.

For example, in the electronic components, micro-mechanical, medical equipment and other extremely sensitive to small errors in the manufacture of products, laser welding can ensure the accuracy and consistency of the joints.

At the same time, the high precision of welding, but also to avoid excessive consumption of materials, thereby improving product quality and production efficiency.

2. Low thermal impact

Unlike conventional welding techniques, the heat input of laser welding is localized and extremely concentrated.

This means that during the welding process, the surrounding material is only subjected to a very small thermal impact zone, thus avoiding the generation of large-scale thermal deformation or internal stress, and reducing the material cracks or warpage and other problems.

This feature is especially in the welding of thin plates or precision parts to show a clear advantage.

3. High performance and fast processing

laser welding machine has a very high energy density, can complete the welding process in an instant, compared with conventional welding technology has a faster processing speed.

Especially in mass production, can significantly shorten the processing time, improve production efficiency.

Not only that, but also high-speed and stable continuous processing, without frequent machine stops, which is a very advantageous technology choice for such as automotive, aerospace industry and other production areas that require high efficiency and precision.

4. Automation and Intelligence

Highly automated welding processes can be realized, whether in simple assembly line production or in conjunction with industrial robots.

Through digital control systems, laser welding can accurately set parameters to ensure stability and consistency from one weld to the next.

Laser welding machines can also be integrated with intelligent monitoring systems for real-time quality inspection and troubleshooting, which not only improves production efficiency, but also reduces downtime and production waste due to improper operation or equipment failure.

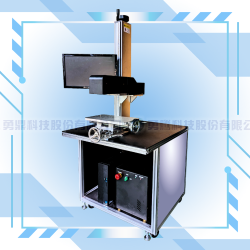

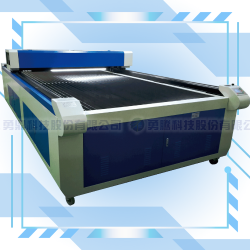

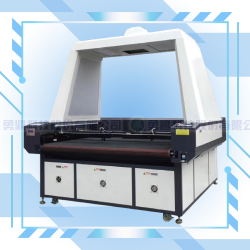

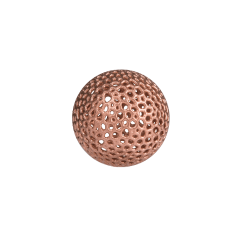

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry