Login

Contact

Description

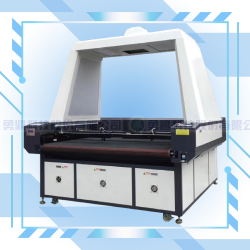

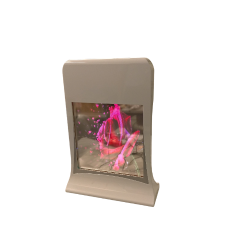

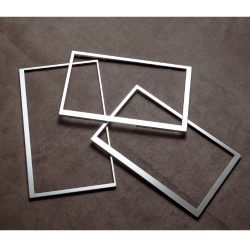

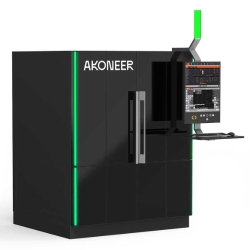

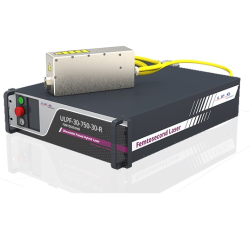

[ Vision positioning automatic edge-finding laser cutting machine ]

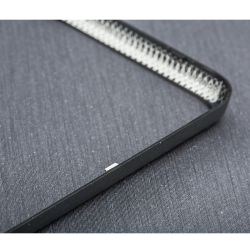

Built-in high-resolution visual recognition system, it can automatically scan and judge the pattern contour, and cut in precise alignment, solving the difficulties of manual error and alignment.

It is especially suitable for cutting the edge of color printing stickers, fabric patterns and soft materials, and supports batch processing.

Enhance the yield and speed, is a garment, packaging and text entrepreneurs.

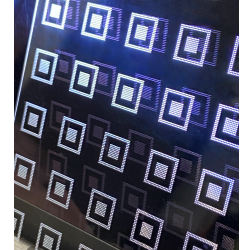

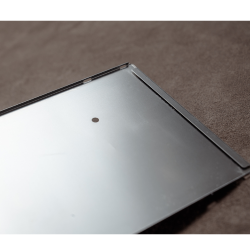

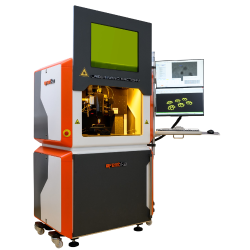

1. Precise Visual Positioning

Through the high-resolution camera and image processing software, it can automatically identify and analyze the specific position and shape of the workpiece to achieve a seamless laser cutting process.

This technology can recognize materials of various shapes and sizes, and can accurately locate both regular and irregular workpieces, significantly improving cutting accuracy.

Because the system automatically adjusts the position, even if the workpiece is slightly shifted on the table, it can be accurately recognized and corrected, reducing material waste and ensuring that the cutting line matches the design exactly.

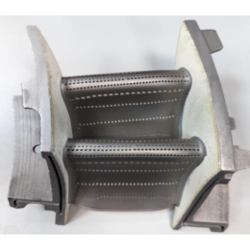

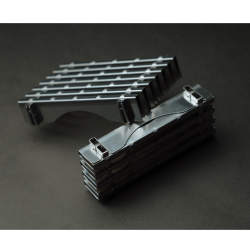

2. Automatic Edge Finding Function

The machine is capable of quickly and automatically recognizing the edge position of the material after it is placed on the cutting table.

Through the built-in sensors or cameras, the machine is able to accurately detect the material's edge and correct the cutting path immediately.

This greatly reduces errors that can occur during manual positioning and ensures the integrity and accuracy of the cut.

Automatic edge searching not only improves material utilization, but also effectively reduces cutting failure or material loss due to positional deviation.

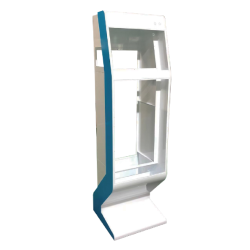

3. Intelligent control system

Provides a more convenient and flexible experience. Usually equipped with touch screen, friendly operation interface, and built-in powerful software platform, it can realize automatic nesting, precise adjustment of cutting path, recording of cutting data and remote monitoring and other functions.

Operators can realize complex cutting tasks through simple command settings. Intelligent control system is also equipped with automatic alarms and maintenance tips to further ensure the safety and stability of production.

4. Reduced manpower requirements

Visual positioning and automatic edge finding technology makes the operation process greatly automated, the operator only needs to simply set the basic parameters, no need to carry out tedious manual calibration or positioning, which greatly reduces the dependence on the operating technology.

Even novices can operate the machine after a short training, saving a lot of labor costs and time.

There is almost no need for continuous monitoring by the operator during the whole process, which further reduces the labor intensity of the personnel and enables the enterprise to allocate manpower resources more effectively.

Built-in high-resolution visual recognition system, it can automatically scan and judge the pattern contour, and cut in precise alignment, solving the difficulties of manual error and alignment.

It is especially suitable for cutting the edge of color printing stickers, fabric patterns and soft materials, and supports batch processing.

Enhance the yield and speed, is a garment, packaging and text entrepreneurs.

1. Precise Visual Positioning

Through the high-resolution camera and image processing software, it can automatically identify and analyze the specific position and shape of the workpiece to achieve a seamless laser cutting process.

This technology can recognize materials of various shapes and sizes, and can accurately locate both regular and irregular workpieces, significantly improving cutting accuracy.

Because the system automatically adjusts the position, even if the workpiece is slightly shifted on the table, it can be accurately recognized and corrected, reducing material waste and ensuring that the cutting line matches the design exactly.

2. Automatic Edge Finding Function

The machine is capable of quickly and automatically recognizing the edge position of the material after it is placed on the cutting table.

Through the built-in sensors or cameras, the machine is able to accurately detect the material's edge and correct the cutting path immediately.

This greatly reduces errors that can occur during manual positioning and ensures the integrity and accuracy of the cut.

Automatic edge searching not only improves material utilization, but also effectively reduces cutting failure or material loss due to positional deviation.

3. Intelligent control system

Provides a more convenient and flexible experience. Usually equipped with touch screen, friendly operation interface, and built-in powerful software platform, it can realize automatic nesting, precise adjustment of cutting path, recording of cutting data and remote monitoring and other functions.

Operators can realize complex cutting tasks through simple command settings. Intelligent control system is also equipped with automatic alarms and maintenance tips to further ensure the safety and stability of production.

4. Reduced manpower requirements

Visual positioning and automatic edge finding technology makes the operation process greatly automated, the operator only needs to simply set the basic parameters, no need to carry out tedious manual calibration or positioning, which greatly reduces the dependence on the operating technology.

Even novices can operate the machine after a short training, saving a lot of labor costs and time.

There is almost no need for continuous monitoring by the operator during the whole process, which further reduces the labor intensity of the personnel and enables the enterprise to allocate manpower resources more effectively.

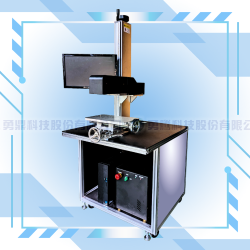

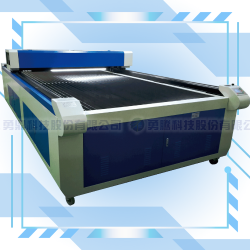

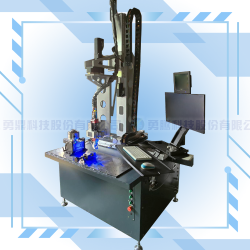

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry