Login

Contact

Description

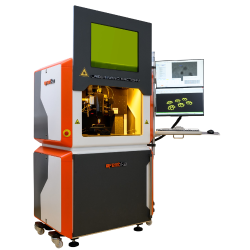

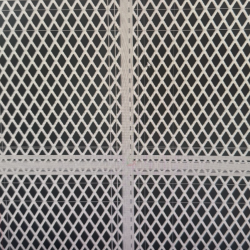

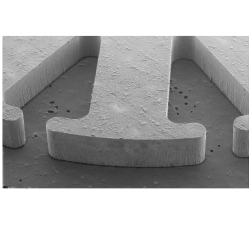

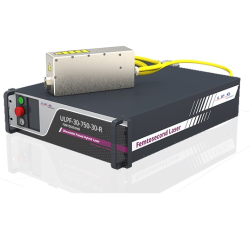

Femtika, a femtosecond laser processing company based in Lithuania, utilizes Multiphoton Polymerization (MPP)—a technology capable of producing arbitrarily shaped polymer structures with micron-level resolution. The process begins by dispensing a polymer material mixed with a photoinitiator onto a glass substrate, followed by pre-baking to prepare the photoresist sample. Next, laser direct writing is employed to fabricate 3D microstructures. Due to the photopolymerization process, the polymer solidifies at the precise locations within the droplet that are exposed to laser radiation. Finally, the microstructure is developed by immersing it in an organic solvent to remove the unpolymerized photoresist.

Thanks to its exceptional ability to produce complex and precise structures, MPP has become a popular choice for the fabrication of microelectronic devices. Its highly focused light source also enables the easy creation of intricate 3D geometries.

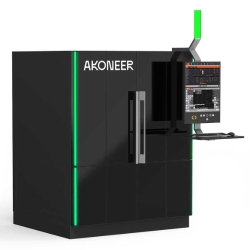

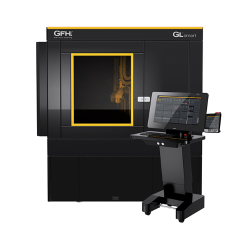

Selective laser etching (SLE) is a subtractive laser technology allowing fabrication of complex-shape 3D glass parts with micrometer precision.

This technology consists of two fabrications steps:

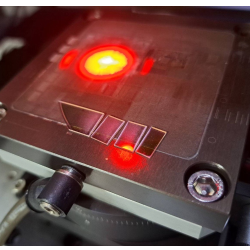

1. Femtosecond laser irradiation

2. Subsequent chemical etching.

Tightly focused femtosecond laser beam induces modifications of transparent material within the focal point of laser beam. By spatially moving the laser focus well-defined structure is written in point-by-point fashion up to substrate surface. Afterward, the sample is immersed in etchant solution, which etches out laser modified areas.

SLE is often used in the manufacturing of electronic devices and other precision components, as it allows for high levels of accuracy and detail in the etched patterns. Additionally, because the laser beam is highly focused, it can be used to etch very small and intricate designs.

Thanks to its exceptional ability to produce complex and precise structures, MPP has become a popular choice for the fabrication of microelectronic devices. Its highly focused light source also enables the easy creation of intricate 3D geometries.

Selective laser etching (SLE) is a subtractive laser technology allowing fabrication of complex-shape 3D glass parts with micrometer precision.

This technology consists of two fabrications steps:

1. Femtosecond laser irradiation

2. Subsequent chemical etching.

Tightly focused femtosecond laser beam induces modifications of transparent material within the focal point of laser beam. By spatially moving the laser focus well-defined structure is written in point-by-point fashion up to substrate surface. Afterward, the sample is immersed in etchant solution, which etches out laser modified areas.

SLE is often used in the manufacturing of electronic devices and other precision components, as it allows for high levels of accuracy and detail in the etched patterns. Additionally, because the laser beam is highly focused, it can be used to etch very small and intricate designs.

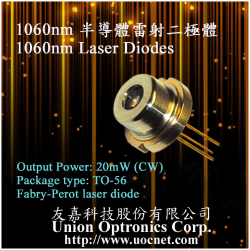

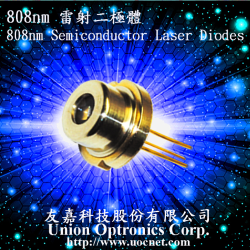

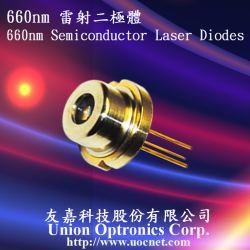

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry