Login

Contact

Description

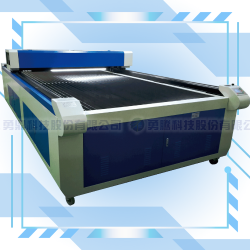

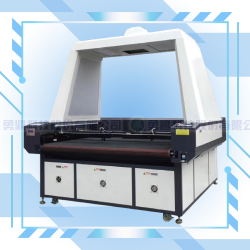

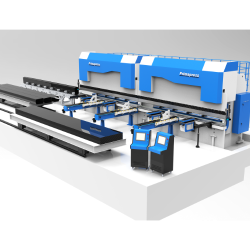

[ CO2 platform laser engraving and cutting machine ]

Combines the dual functions of engraving and cutting to provide a large processing area suitable for large-size acrylic, wood, fabric and leather and other non-metallic materials.

The platform design facilitates loading and unloading, and supports automatic feeding and adsorption fixing to enhance production efficiency.

Widely used in packaging, clothing accessories, advertising display and other industries.

1. Wide range of materials

One of its greatest advantages is its ability to cut a wide range of non-metallic materials, including wood, acrylic, fabric, leather, paper, glass, rubber and some thin metals.

This makes it the tool of choice for many industries, providing an efficient solution for crafts, sign engraving, fashion design, interior decoration and more.

If your business involves the processing of multiple materials, this machine can meet the diversified needs.

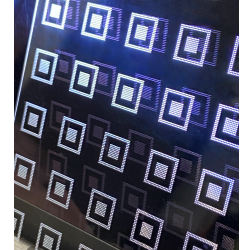

2. High Cutting and Engraving Precision

CO2 laser cutter can perform cutting and engraving operations with extreme precision, often down to the micron level.

This means it can handle extremely delicate patterns, such as tiny font engravings or intricate artistic designs.

For crafts, souvenirs, precision parts, or items that require a high degree of detail, CO2 laser cutters are able to deliver exquisite results and ensure design consistency.

3. High speed and efficiency

Compared with traditional cutting methods, CO2 laser cutting machines offer a significant increase in processing speed, which not only shortens the time required for a single cut, but also demonstrates higher efficiency in mass production.

The automated operating system also makes it ideal for batch production, suitable for large factories or production lines.

This is a significant advantage if your business requires high-volume production with fast delivery times.

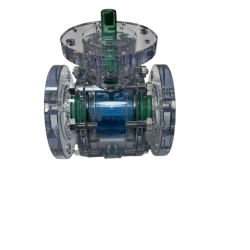

4. Easy and light maintenance

The core components of the machine, such as the laser tubes and lenses, are uncomplicated to replace and maintain, requiring only regular cleaning of the optical components and mechanical parts.

For small businesses and solo entrepreneurs, this means that the machines can be kept in stable operation for a long time without incurring high maintenance costs.

In addition, these machines are usually small enough to be easily installed in small workshops or individual studios, making them ideal for those with limited production space.

Combines the dual functions of engraving and cutting to provide a large processing area suitable for large-size acrylic, wood, fabric and leather and other non-metallic materials.

The platform design facilitates loading and unloading, and supports automatic feeding and adsorption fixing to enhance production efficiency.

Widely used in packaging, clothing accessories, advertising display and other industries.

1. Wide range of materials

One of its greatest advantages is its ability to cut a wide range of non-metallic materials, including wood, acrylic, fabric, leather, paper, glass, rubber and some thin metals.

This makes it the tool of choice for many industries, providing an efficient solution for crafts, sign engraving, fashion design, interior decoration and more.

If your business involves the processing of multiple materials, this machine can meet the diversified needs.

2. High Cutting and Engraving Precision

CO2 laser cutter can perform cutting and engraving operations with extreme precision, often down to the micron level.

This means it can handle extremely delicate patterns, such as tiny font engravings or intricate artistic designs.

For crafts, souvenirs, precision parts, or items that require a high degree of detail, CO2 laser cutters are able to deliver exquisite results and ensure design consistency.

3. High speed and efficiency

Compared with traditional cutting methods, CO2 laser cutting machines offer a significant increase in processing speed, which not only shortens the time required for a single cut, but also demonstrates higher efficiency in mass production.

The automated operating system also makes it ideal for batch production, suitable for large factories or production lines.

This is a significant advantage if your business requires high-volume production with fast delivery times.

4. Easy and light maintenance

The core components of the machine, such as the laser tubes and lenses, are uncomplicated to replace and maintain, requiring only regular cleaning of the optical components and mechanical parts.

For small businesses and solo entrepreneurs, this means that the machines can be kept in stable operation for a long time without incurring high maintenance costs.

In addition, these machines are usually small enough to be easily installed in small workshops or individual studios, making them ideal for those with limited production space.

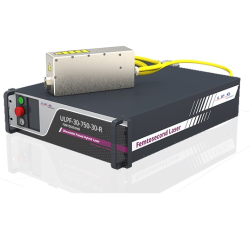

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry